ShockLog® 298 Overview

The ShockLog 298 is the flagship model in the ShockWatch series of impact recorders, which includes the ShockLog 248,

SpotBot, and g-View impact recorders.

With user-programmable impact scale and frequency filters, the ShockLog 298 offers the most flexible option for customers.

The ShockLog 298 monitors impact events, vibration, and internal temperature and provides peak value (time slot) and

summary period journey profile data.

The ShockLog 298 will record the detailed impact curve of up to 870 events.

In addition to impact recording, optional accessories allow you to tailor the ShockLog 298 for your requirements.

Sensors can be added to the ShockLog 298 to record external temperature, humidity, pressure, tilt, and roll conditions.

An optional GPS module allows you to capture the location of alarms and unit summaries.

With the optional cellular module, it’s possible to receive real-time notifications when out of tolerance conditions occur.

An optional satellite module provides connectivity even in areas where cellular service does not exist.

Know with GPS accuracy, the location of out of tolerance conditions and summary positions.

The ShockLog 298 is a highly durable impact recorder that can be configured to monitor critical parameters,

providing an unmistakable alert that an impact to a shipment or equipment may have compromised its integrity,

performance, or safe operation.

Identify Incidents Before Delivery or Installation

ShockLog 298 delivers alerts that your product has encountered conditions that might affect its performance or safety, enabling immediate inspection and remediation at the time shipment is received or before installation in the field.

Protect Your High Value Assets

Customers use the ShockLog 298 impact recorder to:

• Alert recipients and operators to inspect goods and equipment for potential damage

• Determine baseline damage boundaries

• Detect mishandling during shipping, operation and storage, enabling you to identify and assign accountability and take corrective

action

• Make adjustments to product packaging, loading process, carriers, or mode of transport

• Help identify opportunities for improvement through journey profiling

ShockLog® 298 Applications

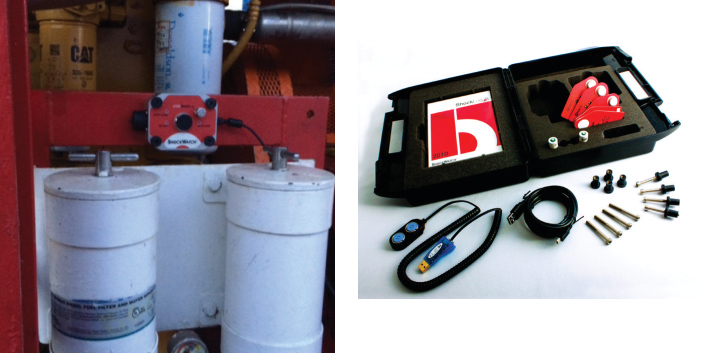

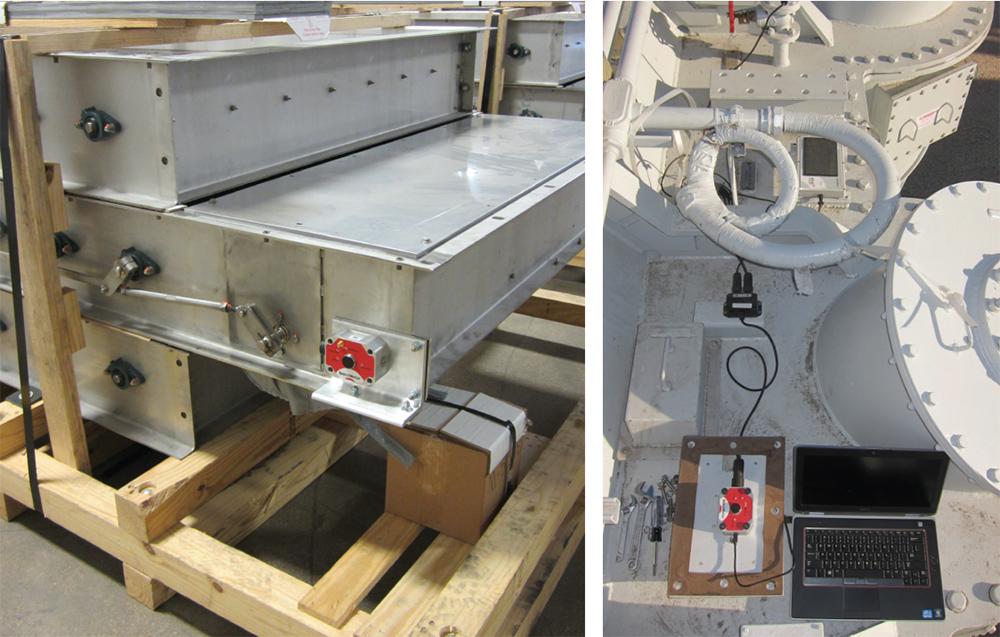

The ShockLog 298 is designed for applications where a variety of conditions are to be monitored.

Below is a small sampling of applications in which the ShockLog 298 has been used:

• Automotive parts: Motors, pumps, windshields, engines, transmissions

• Transportation: Rail cars, barges, cranes, and trucking fleets

• Energy: Oil and gas drilling tools, power transformers, nuclear materials, solar panels, and wind turbines

• Defense and aviation: Lasers, missiles, munitions, gyroscopes, aircraft engines, rocket boosters, and satellites

• Medical and research: Lab equipment, particle accelerator systems, MRI machines, dental chairs, x-ray equipment

Optional Expanded Capabilities

Extend the value of your ShockLog impact recorder by providing more intelligence about the conditions affecting your assets.

• Optional Cellular Module (accessory)

• Optional Humidity/Temperature Sensor (built-in)

• Optional Humidity/Pressure/Temperature Sensor (accessory)

• Optional Tilt & Roll Sensor (built-in)

• Optional GPS Coordinate Recorder (built-in)

• Optional Satellite Module (accessory)

Data Transfer

Products damaged in transportation?

The ShockLog 298 allows you to transmit data via iButton® interface, USB connection, or wireless.

iButtons allow for easy control to setup, download, start and stop the ShockLog. A full journey report can be downloaded using an

iButton while keeping the unit secure and tamperproof. Gain complete programming control and full data access over the USB port.

The cellular module (optional) delivers real-time notifications of conditions during transport. The satellite module (optional) delivers

real-time satellite communication and global position of out of tolerance conditions. A ZigBee Radio Frequency (RF) communication

module (optional) allows the ShockLog to be mounted in difficult-to-access locations and programmed/downloaded over an RF link.

Features

• Records impact events; max peak X, Y, and Z; gRMS; and internal temperature

• Record up to 870 events

• Sensors record direction, amplitude, and duration of impact force

• User-definable warning and alarm levels

• Programmable wake-up values for maximizing battery life

• LED lights for visual notification of alarms and warnings

• Self-contained unit design, free of cables and wires

• IP67-rated, RF-screened

• Option to build temperature/humidity sensor into unit, or add a temperature/pressure/humidity accessory sensor

• Real-time notifications of unacceptable conditions (impact, temperature, humidity, pressure, tilt and roll) with the cellular module (optional) or satellite module (optional)

• Cloud-based interface for monitoring journey conditions in real-time with cellular module (optional) or satellite module (optional)

• Captures coordinates when event occurs at summary intervals with GPS (optional)

• Pinpoints the exact GPS location of an event and summary with GPS (optional)

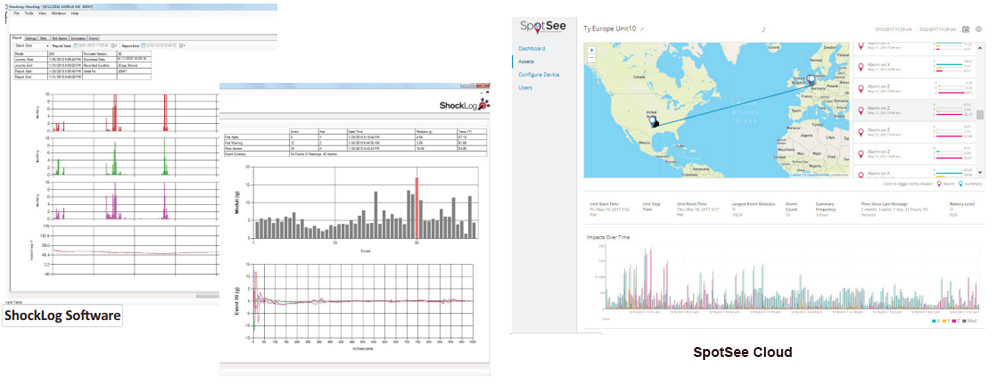

ShockLog Software Allows For Configuration, Data Extraction and Analysis

• Configure your ShockLog device through a simple Windows®-based software program

• Review post journey data to determine what events were responsible for damage

• Export data into programs such as Excel and MatLab for more detailed analysis